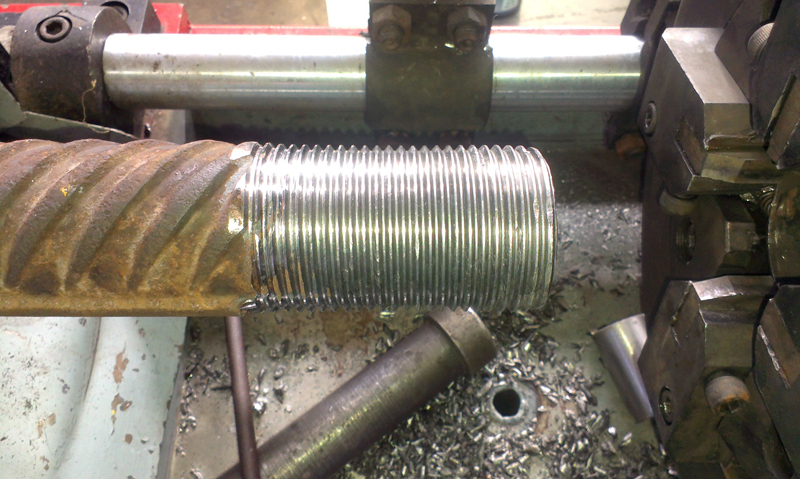

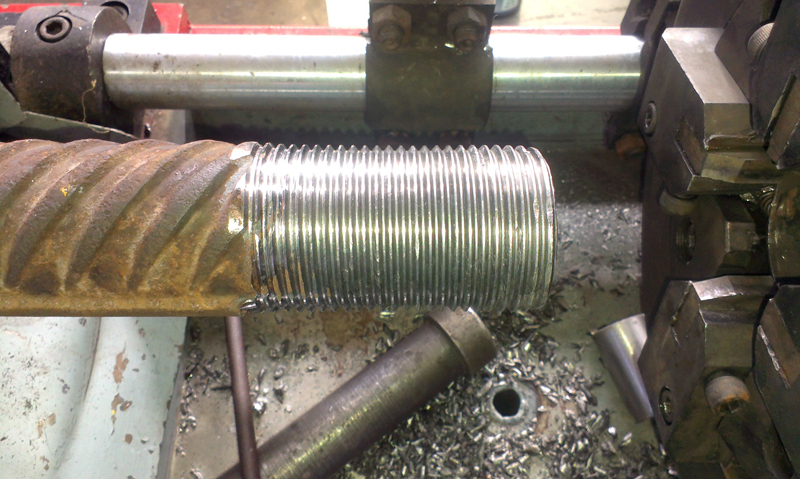

Used Straight Rebar Thread Rolling Machine for Screw

Production Information:

1. The thread form is full and the size is precise;

2.Rolling wheel has long service period, low additive cost of connector;

3.Peel the rebar rib and process thread on rebar end can be made in one step;

4. High production efficiency, it can make 800-1000pcs every day/one machine;

5.It can process rebar of HRB335, HRB400 and HRB500 with diameter from 12-50mm;

6. One handpiece to process left-handed and right-handed thread, which is quite easy to operate and maintain. The cutting tool can be

replaced within only 3-5 minutes;

7. The screw thread diameter are the same which makes it easy to handle and splicing quality is stable and reliable.

Machine Spare Parts:

1. Roller (one set has three pieces);

2. Blade(one set has four pieces);

3. Eccentric Shaft(one set has three pieces);

4.Cooper Bush.

Remarks:

1. Roller Thread Pitch (p=mm) and Rebar Specification ;

p=2/p=2.5 Φ12-Φ22

p=2.5/p=3 Φ25-Φ32

p=3/p=3.5 Φ36-Φ40

2. 60°, 75°thread angle free to chose;

3. Rollers Dimension and the color of machine could be customized by your request.

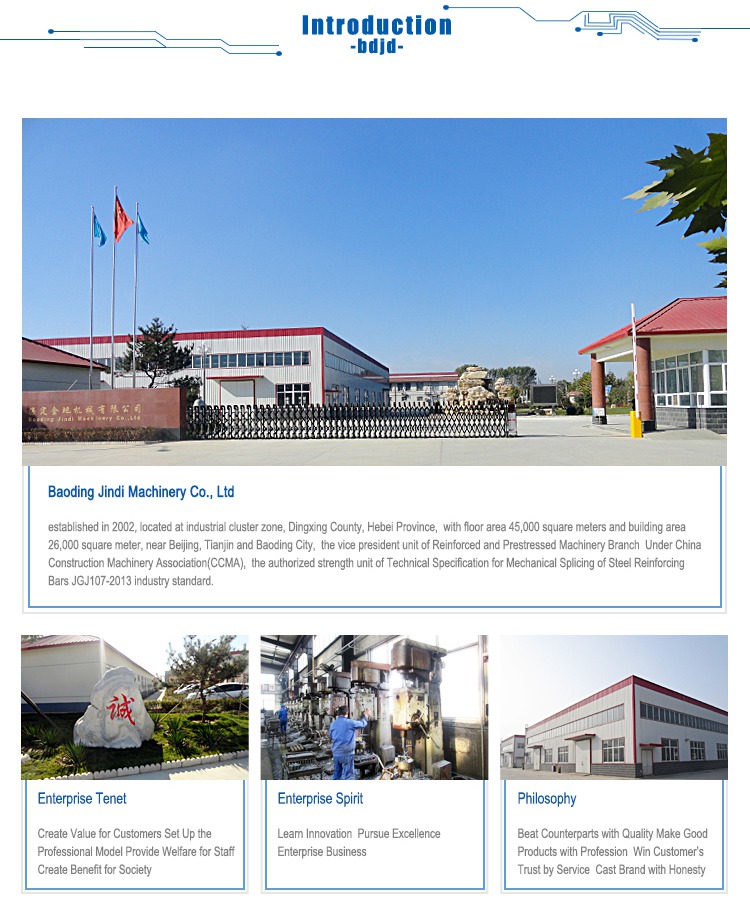

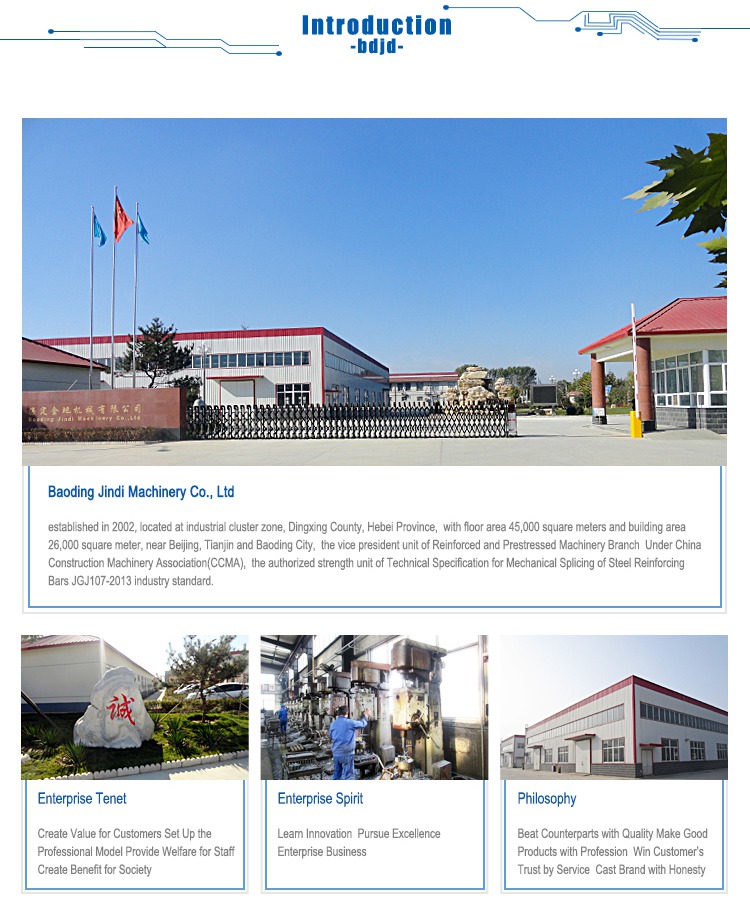

Product Categories : Rebar Thread Rolling Machine > JBG Series Rebar Thread Rolling Machine

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now

Contact Now

Contact Now